|

Innovation-Network Automation 2021/4 |

||||

|

|

||||

|

who does not know these requirements/situations:

|

||||

|

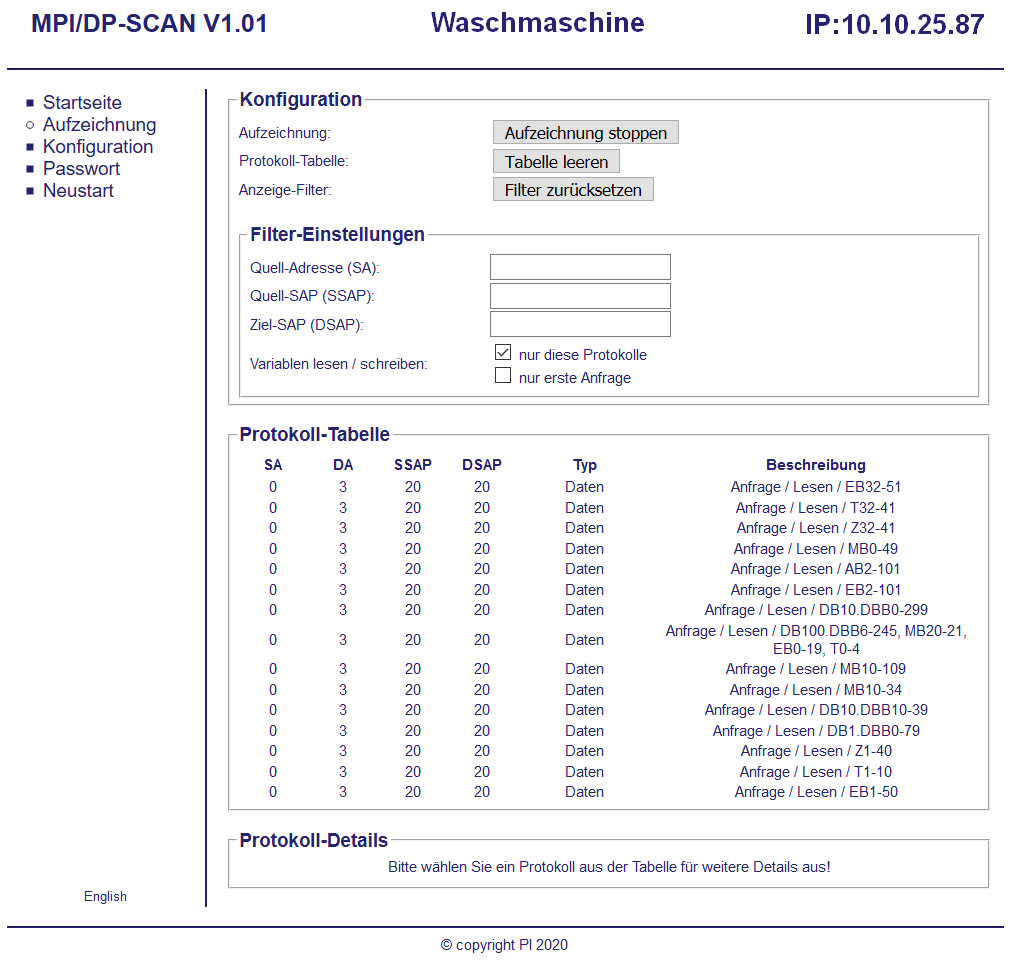

NEW MPI/DP-bus-communication-analyzer NEW Overview&recording of the variable-accesses of an S7-PLC in plain text |

||||

|

S7-panel on S7-PLC or S7-PLC on S7-PLC but parameterization/project no longer available or not known? The BUS-SCANNER listens to the bus and displays

the protocols of the projected control, i.e. the read or written data areas in plain text on the web interface. The accesses can be sorted using filters.

|

|||

| more... | ||||

|

|

||||

|

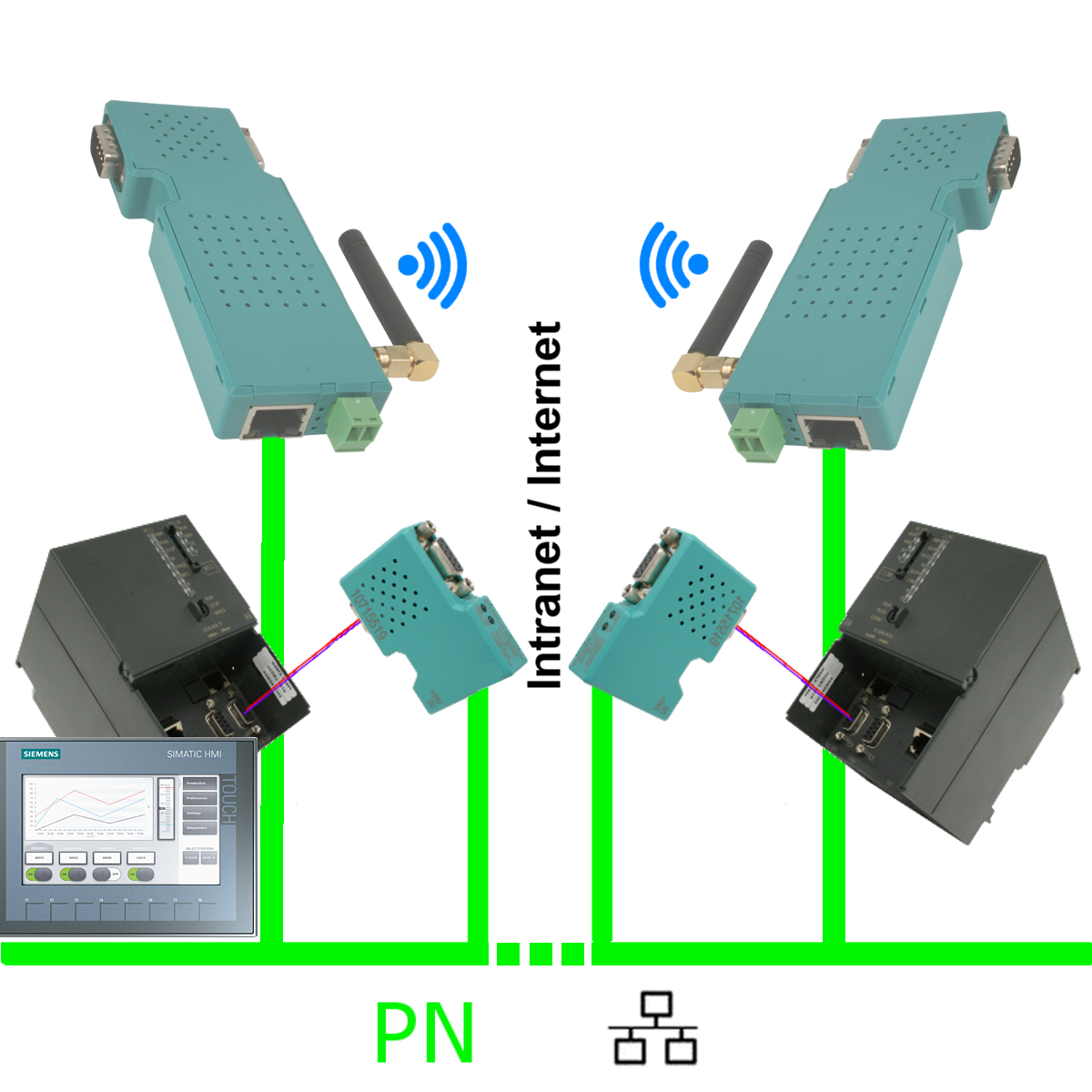

S7-LAN Application: Extension of the MPI/DP communication of a participant via Ethernet (Intranet/Internet) |

||||

|

Your system should be relocated, but the control-panel on the MPI/DP-bus should remain in the same place? Before

you lay extra the purple bus-cable, use the existing network structures (intranet/internet). Connect the panel

to the S7-LAN / S7-BRIDGE and connect the module to the network. Plug in and connect the second S7-LAN / S7-BRIDGE

to the controller, and the panel-communication is transmitted over the network.

|

|||

|

more to S7-LAN...

more to S7-BRIDGE... |

||||

|

|

||||

|

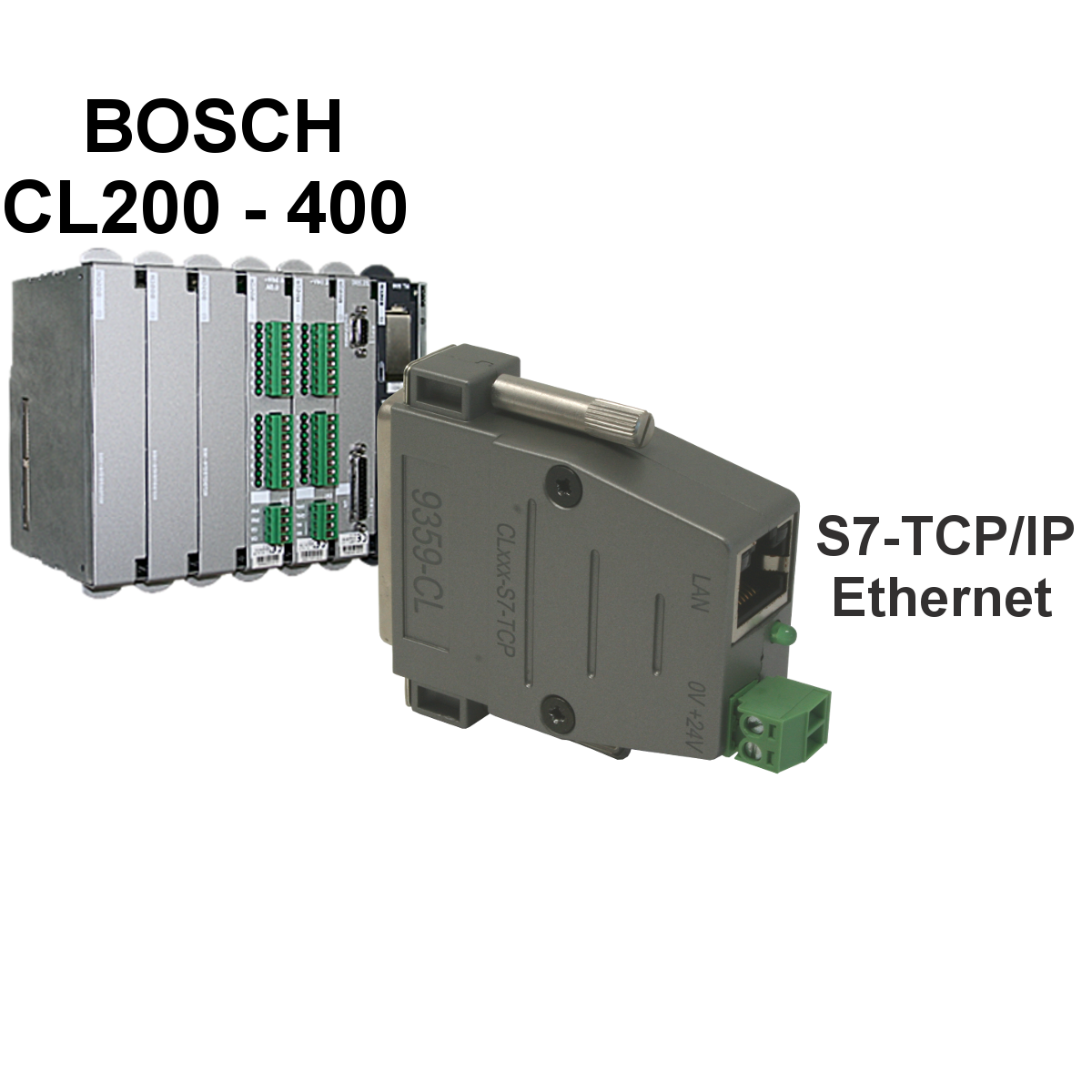

BOSCH-LAN Bosch CL-series-PLC - S7-TCP/IP-gateway |

||||

|

|

|||

| more... | ||||

|

|

||||

|

Universal communication Industry 4.0 Universal - simple - contemporary - one platform for many purposes |

||||

|

Connect or network PLC, CNC, MES or databases, with "Universal Communication Industry 4.0" you can solve the requirements

placed on you. Bring new machines and existing systems together easily in this way. You will hardly find a more difficult requirement

for Industry 4.0. Regardless of whether you have a new, fully digitized factory in the open, green field (greenfield) or an older

existing system (brownfield) - with "Universal Communication Industry 4.0" you connect the top-floor with the shop-floor.

You do not make any compromises when it comes to horizontal digitization. All machine data, master data, database data are defined

as nodes according to IEC 62541, integrated, processed and linked according to your requirements.

|

|||

| more... | ||||

|

|

||||

|

|

||||

|

|

||||

|

|

||||

|

PLC-Communication

-Backup -OPC remote maintenance / remote access ISDN / LTE / internet TCP & ProfiNet -analysis -diagnosis -monitoring S5 & S7 & Panel-connection serial / USB / LAN / WIFI modular analysis- measuring- control- IPC + many sensors |

Process-Informatik

Entwicklungsgesellschaft mbH |

www.process-informatik.de |

|||

|

Im Gewerbegebiet 1 · D-73116

Wäschenbeuren +49 7172 92666-0

+49 7172 92666-0  +49 7172 92666-33

+49 7172 92666-33 |

hotline@process-informatik.de WhatsApp-Hotline  +49 17680706806

+49 17680706806 |

||

DEVELOPER & MANUFACTURER OF COMPONENTS FOR AUTOMATION |

||||

PI-Service-Mail

PI-Service-Mail

ask technician:

ask technician: same day

same day